coalmill

Coal Mill an overview ScienceDirect Topics

A coal mill is a harsh environment in which it is difficult to perform measurements, this means that all the variables are not measurable, eg the actual coal flows in and out of the coal mill are Hydrocarbons from coal James G Speight PhD, DSc, PhD, in Handbook of Grindability2012年5月1日 The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of power plants Derivation and validation of a coal mill model for control2016年1月18日 Firstly, the principles of coal mill is presented, and a coal mill model is established Then we use prediction error method to identify the parameters of the model The Inferential predictive control method of coal mill IEEE

沈阳博海重型机械科技有限公司

2016年4月18日 MPF Coal Mill (Middle Speed Mill) 概述 :MPF(MPS)型辊盘式磨煤机(中速磨煤机)是一种高效节能型磨机,具有煤种适用性广、碾磨效率高、电耗低、寿命长、安全可靠、操作检修方便等优点,广泛用于钢铁、电力、冶 2015年11月1日 Dynamic coal mill model based on conservation laws and empirical relations A model which can replicate the entire milling operation from startup to shutdown Model with A unified thermomechanical model for coal mill operation2007年8月20日 Abstract: This paper presents a multisegment coal mill model that covers the whole milling process from mill startup to shutdown This multisegment mathematical model is Development of a Multisegment Coal Mill Model Using an Coal Mill Control and Optimization Using a Multilayer Structure Abstract: Ball mill coal pulverizing system is a multipleinput multipleoutput (MIMO) process characterized with strong couplings Coal Mill Control and Optimization Using a Multilayer Structure

.jpg)

Classification performance of model coal mill classifiers with

2019年8月27日 摘要: The classification performance of model coal mill classifiers with different bottom incoming flow inlets was experimentally and numerically studied The flow field 2020年4月7日 The main task of a coal mill system is to provide qualified fuel for the pulverized coal boiler In the coal mill system, raw coal is firstly grinded into fine powder, and then dried and transmitted into the boiler by the primary airModeling of Coal Mill System Used for Fault 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical An investigation of performance characteristics and 2016年1月18日 Next, the paper estimates the coal outlet mass flow of the coal mill by using extended Kalman filter (EKF), and the result is compared with the coal flow instruction Finally, we take the estimation of coal outlet mass flow as the new controlled variable and use inferential predictive control method to solve the coal mill control problems The The Inferential predictive control method of coal mill IEEE

Boiler Mill and Coal Pulverizer Performance GE

2 天之前 Major coal mill retrofits; Unique boiler mill solutions; Multiyear agreements; Key performance and flexibility Global fleet and project experience In an everchanging regulatory environment, flexibility and expertise are 2021年8月1日 The coal mill outlet temperature is an important monitoring variable during the operation of a coal mill and needs to be well controlled Low outlet temperature indicates that the pulverized coal is not sufficiently dried, which will decrease the combustion efficiency of coal However, extremely high outlet temperature will make explosions Coal mill model considering heat transfer effect on mass Coal Mill Our company is one of the most important manufacturers of all kinds of coal mills in China, and also the manufacturer to produce the coal mills with various kinds, specifications and types in the worldCoal Mill北方重工2018年11月25日 Ball mill dan pabrik vertikal adalah jenis utama coal mill yang digunakan untuk menggiling batubara menjadi bubuk halus di pabrik bubuk batubara dan pembangkit listrik berbahan bakar batubara Coal mill seperti hammer crusher dan pabrik Raymond juga digunakan untuk menghancurkan dan menggiling batubara Proses penggilingan batubara melibatkan Jenis Coal Mill PDF

.jpg)

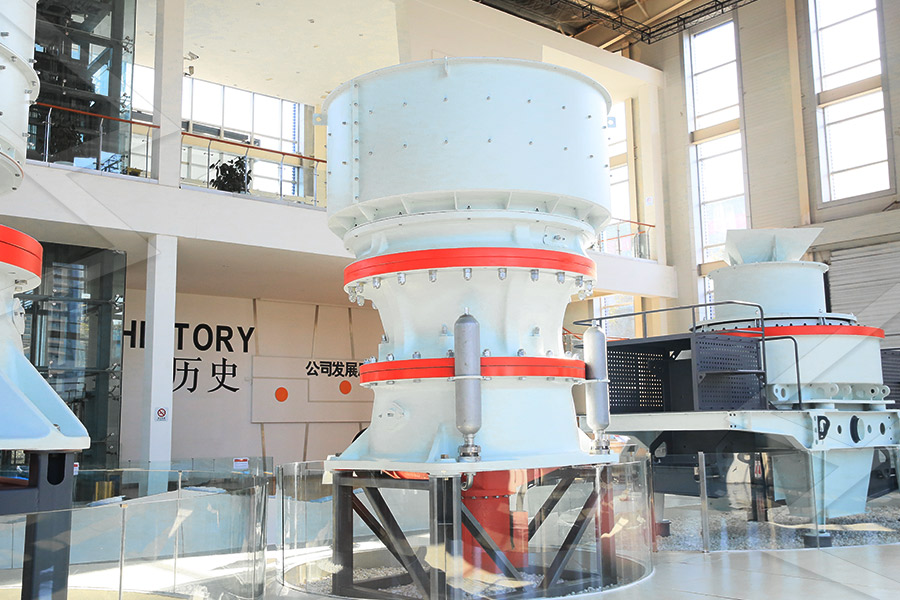

Power Industry Loesche

2024年12月13日 With a low power consumption, low noise and high efficiency operation, the large range of 2, 3 and 4 roller models mean there is a LOESCHE coal mill to suit any application LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange 2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required particle size and temperature at the outlet channel throughout with better classifier performance are crucial indicators that characterize the coal mill performanceAn investigation of performance characteristics and 2015年11月1日 The coal mill grinds the raw coal into fine powder and hot air entering the mill dries and carries the pulverized coal to the burners of the furnace Maffezzoni (1986) emphasized that coal mills are the primary cause of slow load following capability and regular plant shutdowns A major problem in plant’s load control is the inability of the A unified thermomechanical model for coal mill operation2024年10月31日 In discussion: Coal Mill Safety Optimisation of coal mill systems, with fire and explosion protection Protección contra incendios y explosiones en sistemas de molienda de carbón: ¿en qué punto nos encontramos hoy?Coal Mill Safety, Explosion and Fire Protection Consultancy

Dual fault warning method for coal mill based on

2024年5月1日 Coal mill is one of the important auxiliary equipment of thermal power units [6] Before the coal is blown into the furnaces of power plants, the coal mill crushes the coal and dries it If there is an abnormal situation or fault, the flow and quality of pulverized coal cannot be guaranteed In the worst case, the whole thermal power plant may A coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller millsCoal Mill in Cement Plant Vertical Roller MillThis study analyzes different temporal dependency algorithms, including LongShortTermMemory, on a coal mill multivariate timesequence dataset combined with Gaussian Mixture Models to group the operation modes of the coal mill plant The use of GMM and LSTM/BiLSTM models on the multivariate timesequence dataset from the coal mill mechanism Uncovering Insights in Coal Mill Plant Operation Modes 2023年12月14日 Vane Wheel Assembly It is attached to the bowl, directs the coal/air mixture within the grinding zone of the pulverizer by uniformly distributing the transport air through the bowl OD and separator body annulusBowl Mill Coal Pulverizer COAL HANDLING PLANTS

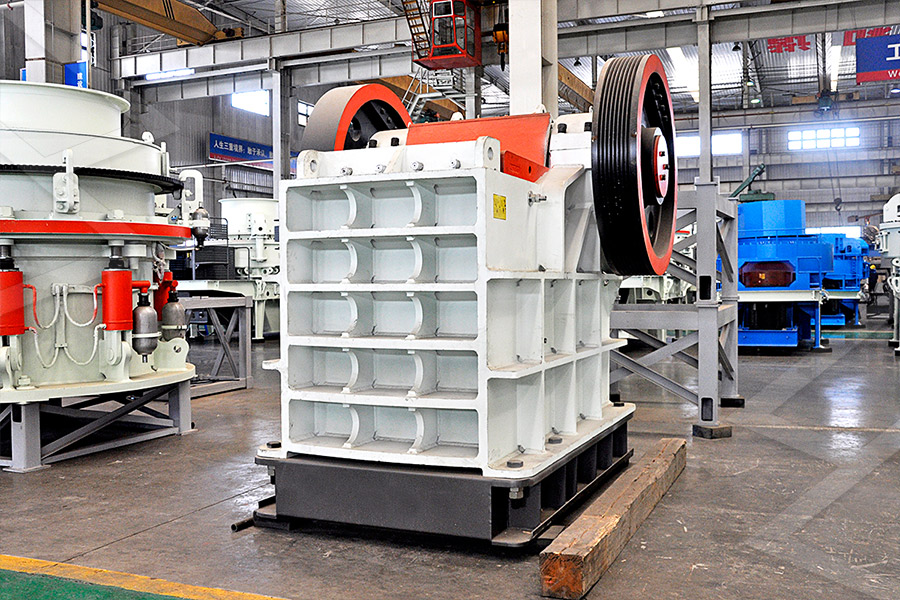

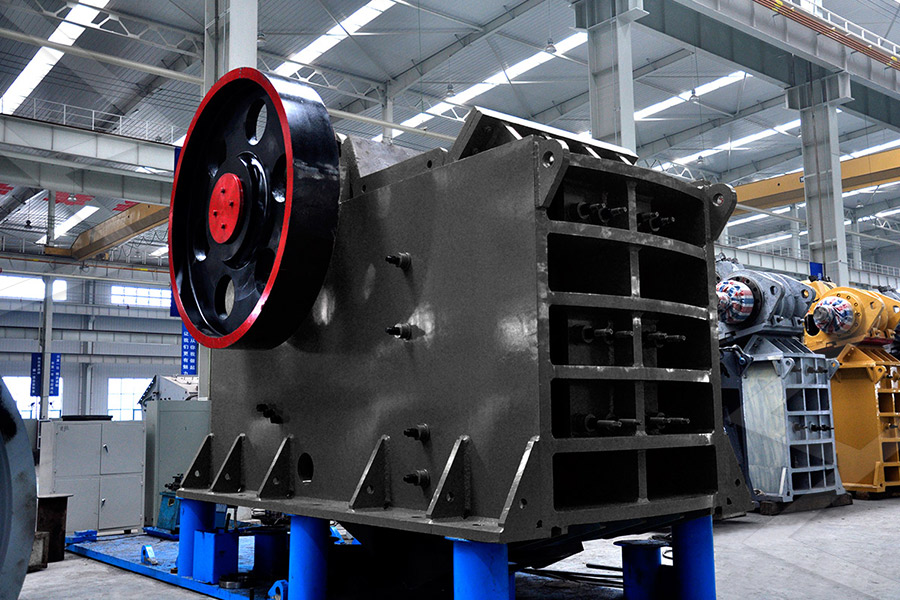

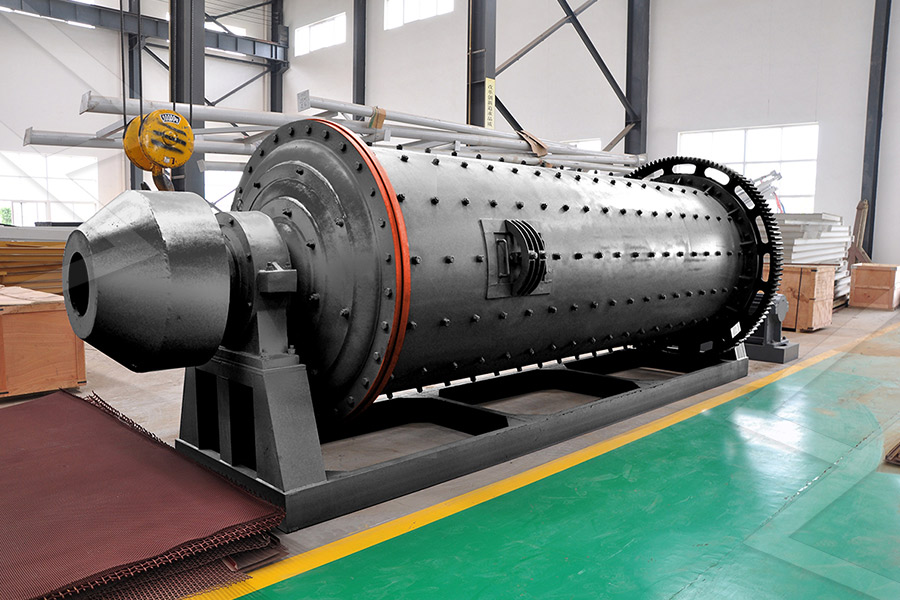

Ball Mill北方重工

MGS double inlet and double outlet coal mill MPG medium speed coal MFQ coal mill MTZ Steel ball coal mill Environmental Protection Equipment Crushing Equipment Rotary Cut Crusher Steel Scrap crushing complete equipment Grinding Equipment MLT desulfurization vertical roller mill2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2024年10月31日 Coal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures This article outlines best practices and precautions to ensure thEnsuring Safety in Coal Mills Coal Mill Safety, Explosion and 2024年11月22日 The ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the most common solution for cement plants Equipped with the highefficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the required finenessATOX COAL MILL FLSmidth Cement

CFB石灰石脱硫剂制备64.jpg)

The Research on Fault Diagnosis Method of the Coal Mill

2013年1月1日 A diagnosis method of coal mill fault based on fuzzy clustering analysis and evidence theory is proposed in this paper This method can solve the fuzzy problem of fault diagnosis, so as to resolve the uncertain problem of fault diagnosis The results of faults diagnosis show that the method is feasible and effective2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to the boiler burners The main types of pulverizers discussed are ball tube mills, bowl mills, ball and race mills, and hammer Coal mill pulverizer in thermal power plants PPT SlideShare2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to Modeling of Coal Mill System Used for Fault Ball mill coal pulverizing system is a multipleinput multipleoutput (MIMO) process characterized with strong couplings and nonlinearities Conventional control methods maybe work well initially, but will deviate from optimal work point for a period of time and even cease to be functionally effective A multilayer structure with direct control and optimization is presented for the control Coal Mill Control and Optimization Using a Multilayer Structure

.jpg)

Monitoring Model of Coal Mill in Power Plant Based on Big

In order to monitor the wear condition of grinding roller of coal mill in power plant and improve the reliability of production equipment, it is necessary to establish a state monitoring model with high accuracy and good prediction effect It has been shown that the power of coal mill can reflect the wear degree of grinding roller If the voltage and power factor of coal mill are constant 2015年8月1日 It has the ability to perform online parameter estimation, mill performance monitoring, fault diagnosis and prognosis, early alarming, and problemsolving solutions J Wang et al [126], [127], [128] developed a technique for monitoring the condition of the mill, which is based on the sixsegment coal mill model developed by JL Wei et al Review of control and fault diagnosis methods applied to 2022年7月7日 Coal Mills are used to pulverize and dry to coal before it is blown into the power plant furnace Operation The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particlesCoal Mills SolidsWiki2023年8月28日 Coal Mill Pulverizer in Thermal Power Plants; Contact Info Phone: +86 +86 : info@bellianmachinery Address: West Fourth Ring Road, Zhengzhou Hightech Zone Follow Us Get In Touch SEND about usCoal Mill in Thermal Power Plant: Enhancing Efficiency and

.jpg)

Coal Pulverizer – Power Plant Pall Corporation

2 天之前 Pulverizing coal into a fine powder enables it to be burned efficiently, like a gas, improving combustion Enhance coal pulverizer performance with Pall solutions2024年5月1日 Coal mill is one of the important auxiliary equipment of thermal power units [6] Before the coal is blown into the furnaces of power plants, the coal mill crushes the coal and dries it If there is an abnormal situation or fault, the flow and quality of pulverized coal cannot be guaranteed In the worst case, the whole thermal power plant may Dual fault warning method for coal mill based on2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns Therefore, an algorithm has been developed that enable online detection of abnormal conditions and malfunctions of an operating mill Based on calculated diagnostic signals and defined Detection of Malfunctions and Abnormal Working Conditions of a Coal Mill2013年3月1日 Therefore, for coal mill control the application of NMPC is a recommended solution 8 Conclusions In the present paper, the modeling of a vertical roller pressure coal mill was addressed As a result, a nonlinear model has been developed and validated to predict the coal mill behavior during start up and normal operationNonlinear coal mill modeling and its application to model

.jpg)

The Inferential predictive control method of coal mill IEEE

2016年1月18日 Next, the paper estimates the coal outlet mass flow of the coal mill by using extended Kalman filter (EKF), and the result is compared with the coal flow instruction Finally, we take the estimation of coal outlet mass flow as the new controlled variable and use inferential predictive control method to solve the coal mill control problems The 2 天之前 Major coal mill retrofits; Unique boiler mill solutions; Multiyear agreements; Key performance and flexibility Global fleet and project experience In an everchanging regulatory environment, flexibility and expertise are Boiler Mill and Coal Pulverizer Performance GE 2021年8月1日 The coal mill outlet temperature is an important monitoring variable during the operation of a coal mill and needs to be well controlled Low outlet temperature indicates that the pulverized coal is not sufficiently dried, which will decrease the combustion efficiency of coal However, extremely high outlet temperature will make explosions Coal mill model considering heat transfer effect on mass Coal Mill Our company is one of the most important manufacturers of all kinds of coal mills in China, and also the manufacturer to produce the coal mills with various kinds, specifications and types in the worldCoal Mill北方重工

.jpg)

Jenis Coal Mill PDF

2018年11月25日 Ball mill dan pabrik vertikal adalah jenis utama coal mill yang digunakan untuk menggiling batubara menjadi bubuk halus di pabrik bubuk batubara dan pembangkit listrik berbahan bakar batubara Coal mill seperti hammer crusher dan pabrik Raymond juga digunakan untuk menghancurkan dan menggiling batubara Proses penggilingan batubara melibatkan 2024年12月13日 With a low power consumption, low noise and high efficiency operation, the large range of 2, 3 and 4 roller models mean there is a LOESCHE coal mill to suit any application LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange Power Industry Loesche2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required particle size and temperature at the outlet channel throughout with better classifier performance are crucial indicators that characterize the coal mill performanceAn investigation of performance characteristics and 2015年11月1日 The coal mill grinds the raw coal into fine powder and hot air entering the mill dries and carries the pulverized coal to the burners of the furnace Maffezzoni (1986) emphasized that coal mills are the primary cause of slow load following capability and regular plant shutdowns A major problem in plant’s load control is the inability of the A unified thermomechanical model for coal mill operation

.jpg)

Coal Mill Safety, Explosion and Fire Protection Consultancy

2024年10月31日 In discussion: Coal Mill Safety Optimisation of coal mill systems, with fire and explosion protection Protección contra incendios y explosiones en sistemas de molienda de carbón: ¿en qué punto nos encontramos hoy?