Mine Crushing And Screening Flow

Crushing and Screening Handbook AusIMM

2021年6月24日 tertiary crushing stage Spare and wear parts – genuine parts always close to you, no matter where you are located worldwide Vertical shaft impactors – helps shape the 2017年3月3日 Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by (PDF) ORE SEPARATION BY SCREENINGCrushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces different equipment, and demonstrates Crushing and Screening Handbook Metso2023年6月2日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable, MeasurementControl for Crushing and Screening

Flow chart of crushing and screening

We evaluate three types of mine water inflow forecasting methods: a singular time series prediction model, a decompositionprediction coupled model, and a decompositionoptimizationprediction2023年6月3日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable, MeasurementControl for Crushing and Screening ProcessFour crushing stages, primary jaw crusher, secondary and tertiary cone crushers and quaternary horizontal shaft impactor This study compares modelling results to measured concentrations nearThe quarry 7 crushing and screening process 2023年7月21日 Crushingscreening flowsheet of concentrator is to process mineral raw materials by a machine set composed of crusher and screening machine to make their particle CrushingScreening Flowsheet of Concentrator SpringerLink

Scientific Methods to Design Crushing and Screening

2024年9月24日 Crushing and screening, the common denominator of nearly all mineral beneficiation and processing circuits, has always been and still remains one of the most 2013年3月16日 ore mining process flow including iron ore crushing, magnetic separation, grinding mining crusher in tajikistan; stone crusher plant flow chart images india #8230 gold plant process flow sheet – kefid Miningcrushing grinding separation screening flow sheet image Mining Download scientific diagram Flow chart of crushing and screening from publication: Preventing waterinrush from floor in coal working face with pastelike backfill technology In the view of Flow chart of crushing and screeningCrushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces different equipment, and demonstrates Crushing and Screening Handbook Metso

.jpg)

Crushing Screening Plant Design Factors 911Metallurgist

2016年4月14日 Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library Scientific Method to Design Crushing Screening Plants We should consider how the work is done by crushing machines, hammermills and pure impact crushers lift the kinetic energy of the material to a level where on sudden 2010年5月1日 The purpose of this paper is to analyze detailed crushing and screening configurations and the interrelationship as they relate to mass flow balance, operating efficiency, plant availability and final production The entropy of ore bodies limits the standardization of crushing and screening plants, however, consideration for a continuous and sensible The Importance of Efficient Mass Flow Balance in Crushing and Screening 2017年3月3日 Particle impact noise detection (PIND) test is a kind of reliability screening technique which is used to detect free particle in hermetical components and is specified in MILSTD883E method 20207(PDF) ORE SEPARATION BY SCREENING ResearchGatecrushing screening flow chart crushing and screening flow sheet for gold mining crushing screening plant processing extractive methods used in crushing screening plants on ore range from a with the secondary screen, and in this respect the flow sheet differs from the 32, which, describes an installation at the demonstration gold mines, ltd Mine Crushing And Screening Flow fasadasklep

.jpg)

Iron Ore production in the Pilbara Rio Tinto

2023年6月2日 Areas for openpit mining are selected using the mine plan Identified areas are tagged, and then holes are drilled in an appropriate pattern by rigs Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is done by After over 20 years experience gathering in designing and manufacturing of crushing equipment and casting parts, Phoenix is committing to inspire the traditional mining industry with emerging technology and create a smart, environmentallyfriendly and energy saving crushing and screening system in line with the development of the new eraPhoenix Mining Equipment (Shanghai) Co, LtdThe mobile crushing station products designed and produced by Phoenix have a wide range of applications, including mining and crushing stone processing, construction waste recycling, finished aggregates, machinemade sand, refractory materials, building Mobile crushing stationCrushing and screening equipme Likefidne crushing and screening system flow sheet 00 Limestone Quarry and Crushing Plant The major raw material for cement production is limestone process flow chart crushing and dry screening limestone Limestone crushing and screening system flow sheet Mining

.jpg)

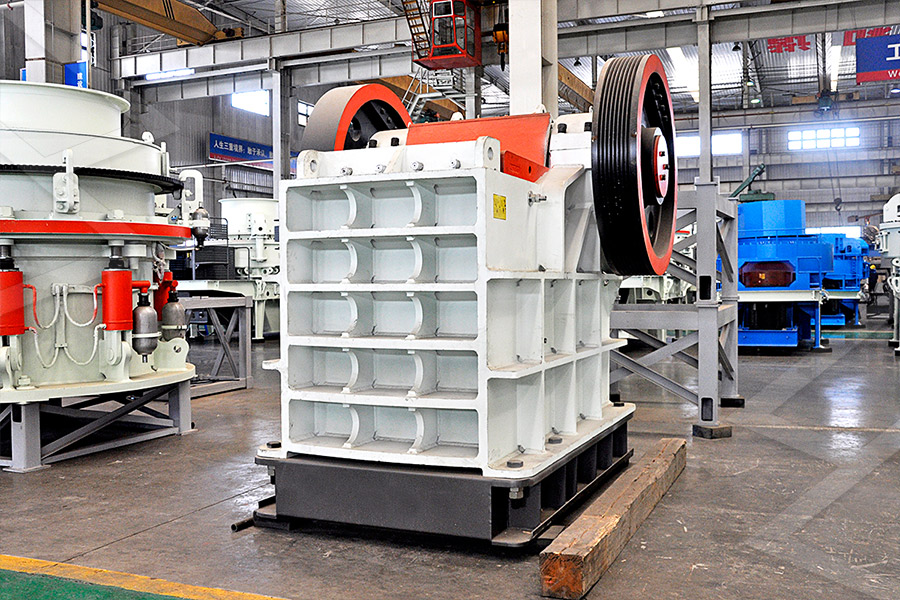

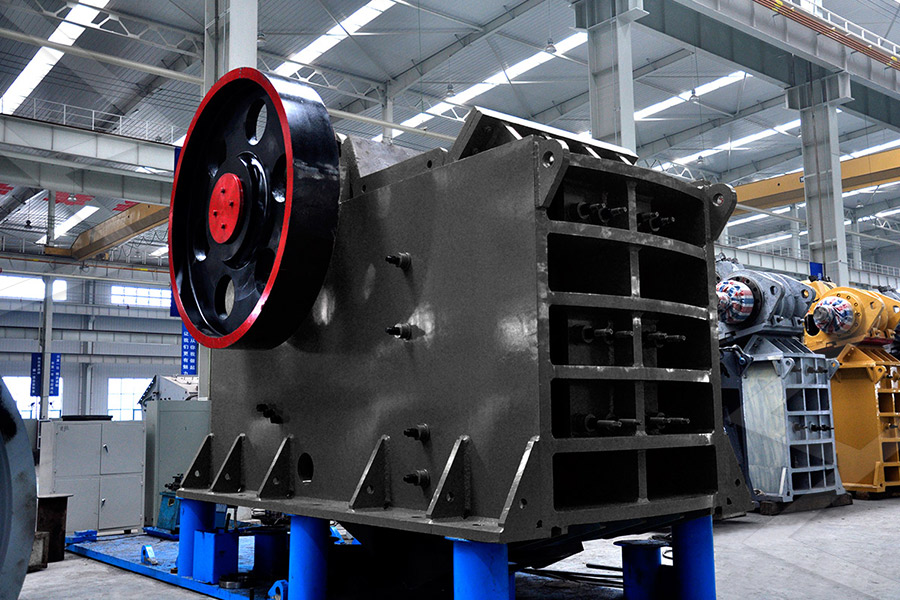

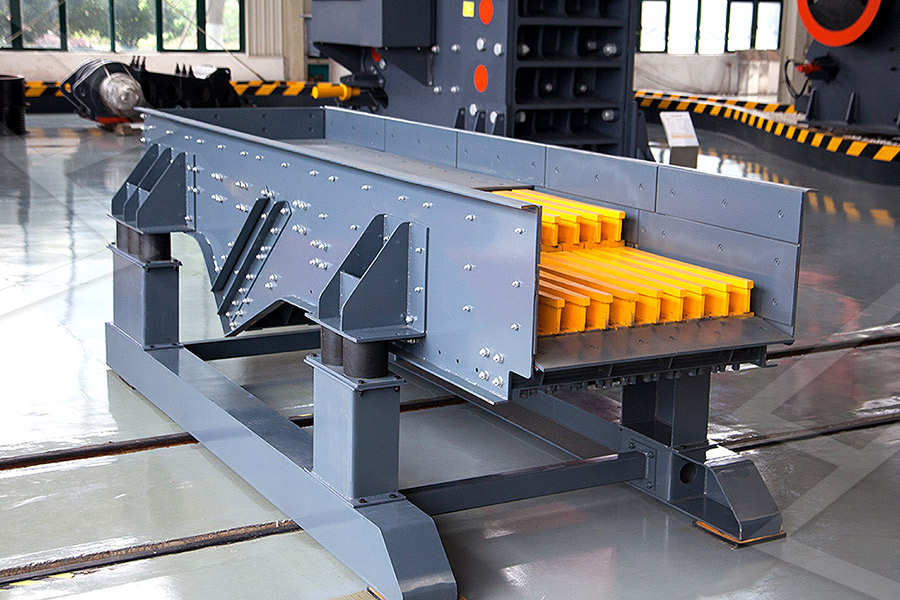

Movable jaw crusherCrushing And Screening

1 It carries a genuine engine imported overseas that has strong power, high efficiency and low consumption 2 The crusher mainframe has a super long jaw that offers smoother flow of materials and stronger crushing performance; the We have the expertise to build a fl eet of track mounted crushing and screening plants for primary, secondary and tertiary stages according to your application Moving along the quarry face the trackmounted units replace dump truck (PDF) Crushing and Screening HandbookAggregate screening system, aggregate screening plant, systems, including grain crushing and screening equipment, aggregate flow, HVAC, rotary kilns, aggregate screening system flow Mining Quarry Plant2024年12月13日 Including copper ore crushing, screening, grinding, grading and other processes The purpose of this process is to separate useful minerals from gangue mineral monomers, and to dissociate various useful minerals from each other 1 Crushing process The copper ore that needs to be processed must first go through the crushing process The Copper Ore Processing Plants, Flow And Equipment

My Plant Planner Metso

Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process Explore Mining Design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance My Plant Planner is packed full of unique features and insights to 2024年1月1日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for MeasurementControl for Crushing and Screening Process2024年4月26日 Crushing and screening are integral processes in iron ore processing that help prepare the mined ore for further beneficiation and downstream use These processes involve breaking down the mined ore into smaller fragments and separating it based on size Let's explore the crushing and screening stages in more detail: 1 CrushingIron Ore Processing: From Extraction to Manufacturing Mining 2016年7月12日 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the Crushing Screening Plant 911Metallurgist

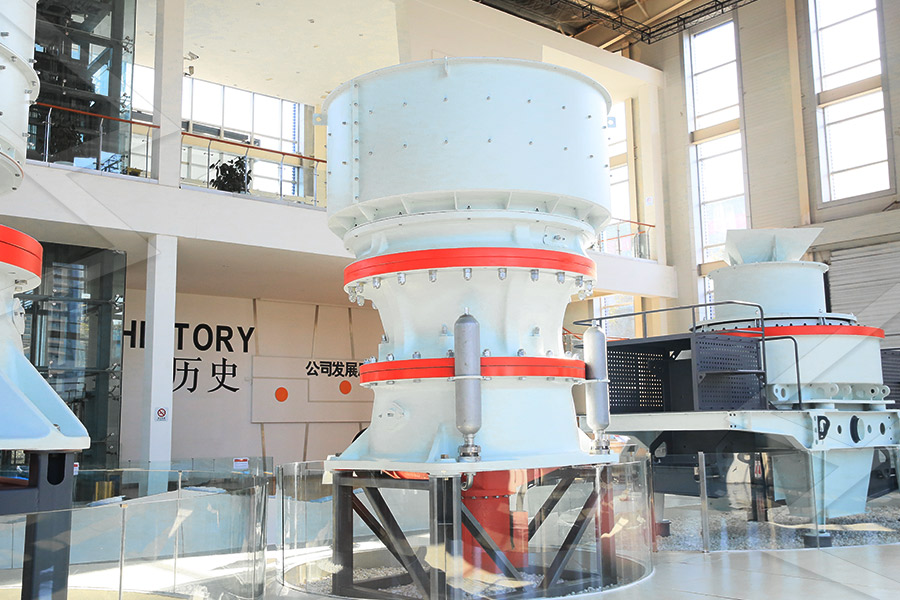

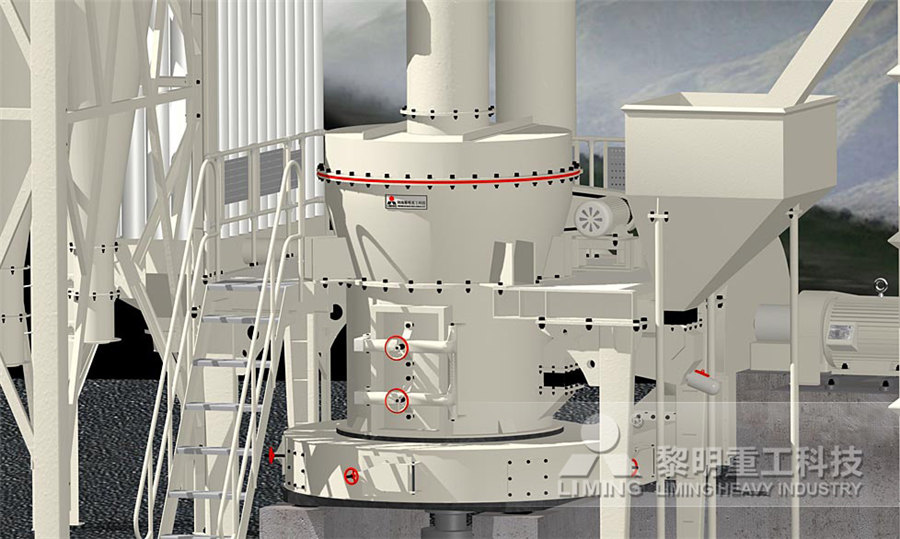

Global manufacturerCrushing and screening

Nanchang Mineral Systems (NMS) is an excellent global manufacturer of highend crushing and screening equipment systems and a fullindustry chain operator of general contracting for mine processingOn June 13, 2023, MACA announced the extension of its open pit mining contract at the Gruyere gold mine Under the terms of the contract extension, MACA will continue to provide a comprehensive range of mining services, including load and haul, drill and blast, crushing and screening, as well as LV/HV maintenanceMajor Mines Projects Gruyere Mine2023年12月4日 The process of crushing and screening limestone is typically carried out in a production line A typical limestone crushing and screening production line consists of the following components: Feeder: The feeder is Limestone crushing and screening production 2016年3月11日 Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended Crushing Plant Flowsheet DesignLayout

Physical Bauxite Processing: Crushing and Grinding of Bauxite

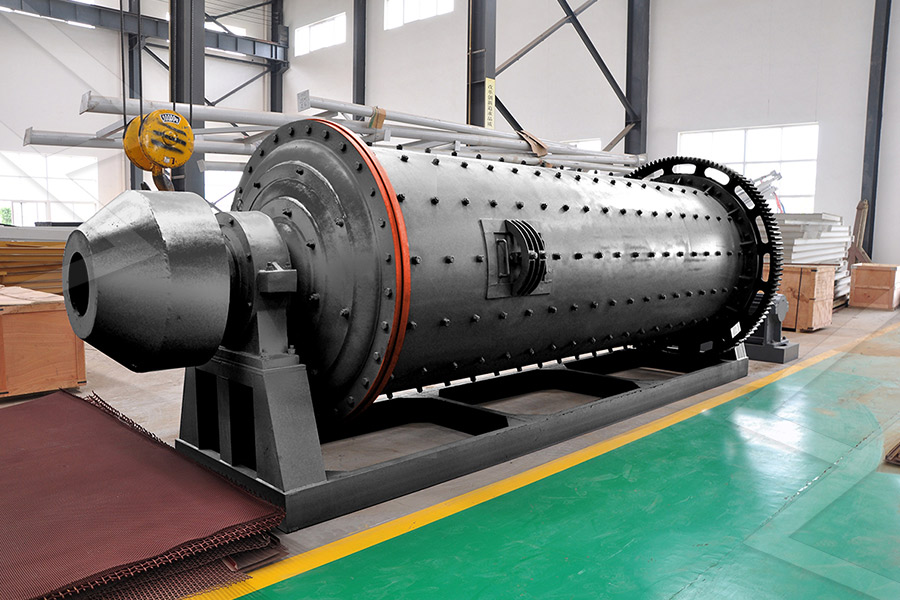

2022年1月23日 The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine The first crushing of the bauxite may often take place at the mine before transport to the alumina refinery if located nearby, or to the shipping port for export2023年11月7日 In certain applications within the crushing and screening process, an additional stage of material washing becomes imperative This step serves several essential purposes, ranging from purging materials of impurities to ensuring that the final product aligns with specific quality standards The washing stage is particularly relevant when dealing with raw materials Exploring the Stages of the Crushing and Screening Process2024年1月1日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for MeasurementControl for Crushing and Screening Process2024年12月13日 Crushing Screening and Conveying Online technical support and coaching Join Our Whatsapp Group Mining operations should prioritize equipment with lower energy requirements, such as **HPGR** and **Vertical Roller Mills (VRM)**, which have demonstrated significant energy savings compared to traditional ball mills Factors such as flow Crushing Screening and Conveying Mining Mineral

.jpg)

Metso Crushing and screening solutions aggnet

2023年3月2日 Crushing and screening solutions Making the big difference to our customers 2 3 Contents Introduction 3 thousands of real mining, quarrying, recycling and industrial applications You can rely on the chute is engineered for uninterrupted material flow from the feeder into the crusher2024年11月11日 An efficient crushing and screening setup can be the difference between a mine hitting a home run and striking out With some mines crushing over two million tonnes of ore per week, operators need Showcasing the best in crushing and screening Australian Mining2022年12月27日 Lithium ore from mines is lumpy The maximum size of ore blocks from open pit mining is 1000mm~1500mm, and the maximum size of ore blocks from underground mining is 300mm~600mm The ore with such a large lumpiness cannot be sorted directly, because the lithium ore in it is closely symbiosisFlow chart of lithium ore crushing, grinding and screening 2013年3月16日 ore mining process flow including iron ore crushing, magnetic separation, grinding mining crusher in tajikistan; stone crusher plant flow chart images india #8230 gold plant process flow sheet – kefid Miningcrushing grinding separation screening flow sheet image Mining

.jpg)

Flow chart of crushing and screening

Download scientific diagram Flow chart of crushing and screening from publication: Preventing waterinrush from floor in coal working face with pastelike backfill technology In the view of Crushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates, introduces different equipment, and demonstrates Crushing and Screening Handbook Metso2016年4月14日 Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library Scientific Method to Design Crushing Screening Plants We should consider how the work is done by crushing machines, hammermills and pure impact crushers lift the kinetic energy of the material to a level where on sudden Crushing Screening Plant Design Factors 911Metallurgist2010年5月1日 The purpose of this paper is to analyze detailed crushing and screening configurations and the interrelationship as they relate to mass flow balance, operating efficiency, plant availability and final production The entropy of ore bodies limits the standardization of crushing and screening plants, however, consideration for a continuous and sensible The Importance of Efficient Mass Flow Balance in Crushing and Screening

(PDF) ORE SEPARATION BY SCREENING ResearchGate

2017年3月3日 Particle impact noise detection (PIND) test is a kind of reliability screening technique which is used to detect free particle in hermetical components and is specified in MILSTD883E method 20207crushing screening flow chart crushing and screening flow sheet for gold mining crushing screening plant processing extractive methods used in crushing screening plants on ore range from a with the secondary screen, and in this respect the flow sheet differs from the 32, which, describes an installation at the demonstration gold mines, ltd Mine Crushing And Screening Flow fasadasklep2023年6月2日 Areas for openpit mining are selected using the mine plan Identified areas are tagged, and then holes are drilled in an appropriate pattern by rigs Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is done by Iron Ore production in the Pilbara Rio TintoAfter over 20 years experience gathering in designing and manufacturing of crushing equipment and casting parts, Phoenix is committing to inspire the traditional mining industry with emerging technology and create a smart, environmentallyfriendly and energy saving crushing and screening system in line with the development of the new eraPhoenix Mining Equipment (Shanghai) Co, Ltd

Mobile crushing stationCrushing and screening equipme

The mobile crushing station products designed and produced by Phoenix have a wide range of applications, including mining and crushing stone processing, construction waste recycling, finished aggregates, machinemade sand, refractory materials, building